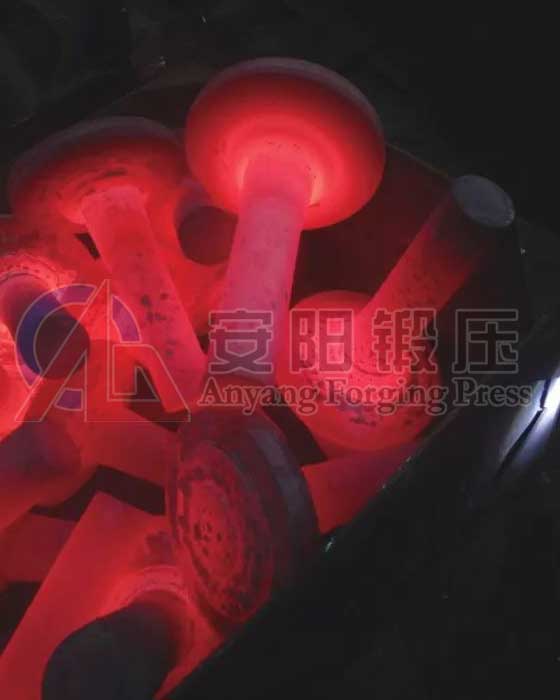

Forging steel ball process

The whole bar is heated in the medium frequency induction furnace —— hot cutting of bar shearing machine - pre-forging of air hammer - final forging of air hammer - subsequent heat treatment. the forging process of The air hammer is suitable for all kinds diameter of steel balls, especially large diameter and very large diameter steel balls. in one equipment, the steel balls with large diameter span can be produced and the process is flexible and suitable for various batch production.

In the process, in order to improve efficiency, we design a air hammer for pre -forging, and another air hammer for final forging. But in fact, a pneumatic hammer can also complete to forge.

Steel Ball Forging Line Flow Chart

Rolling steel ball process

The rolling ball is the process of continuous deformation of the heated bar on the skew rolling mill to obtain the steel ball, the process is as follows:

The whole bar heating of medium frequency induction furnace - continuous rolling of skew rolling mill - subsequent heat treatment

The automation degree of rolling ball is very high, the production efficiency is much higher than the forging line, can produce the diameter of Ф125mm below the ball, rolling ball production line is also used for mass production, have a high requirements for the power of the production workshop

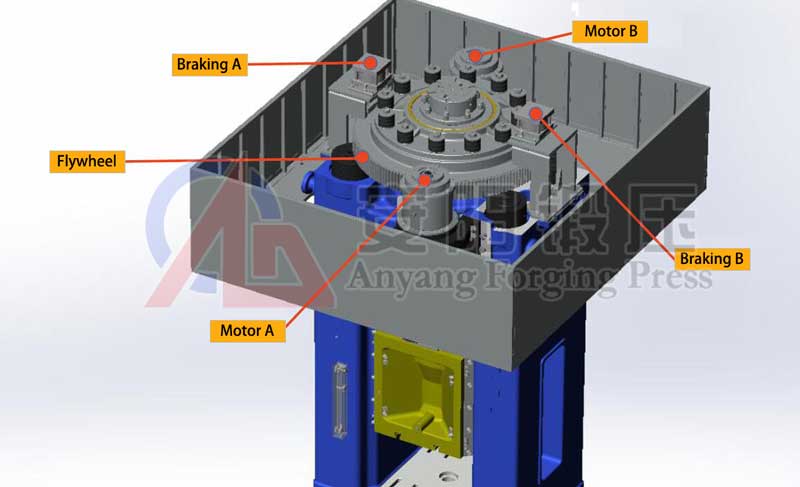

Forging and rolling steel ball process

Heating of whole bar in the medium frequency induction furnace —— hot shear of hydraulic shear - pre - forged steel ball of press ( high direction forming ellipse length ) - roll mill rounding forming - follow - up heat treatment

The rolling process can also be used to produce steel balls of various diameters, but for the reason of investment and efficiency, it is usually used to produce Ф 100 - Ф 200 mm diameter steel balls, which has achieved a better return on investment.

General heat treatment process about steel ball

The purpose of heat treatment of steel ball is to obtain the steel ball with high hardness and certain impact toughness, and adopt quenching process. The steel balls produced by various processes in order to improve the hardness and harden ability. The material uses high carbon and high chromium steel, before the forging and rolling, the heating temperature of 950 - 1050 ℃, after forging ,isothermal to 800 ℃, quenching, and then low temperature tempering.

Isothermal and quenching adopt continuous process, isothermal machine and quenching machine are connected in series with the production line, and the reasonable matching efficiency is obtained. the low temperature tempering has two forms, namely, online low temperature tempering and off-line low temperature tempering, which are related to the production, equipment floor area and other factors.

|

|

Steel Ball Surface Quality |

Quality of Steel Ball Center |

Productivity |

Dynamic Matching |

Manual Skill Requirements |

Manyal Labor Intensity |

Adaptive Batch |

Adapt to the Diameter of Steel Ball |

Investment Intensity |

Process Flexibility |

|

Forging steel ball |

best |

best |

low |

low |

high |

high |

medium and small quantity |

All diameter |

low |

good |

|

Rolling steel ball |

general |

general |

high |

high |

general |

low |

large quantities |

Ф20-125 |

high |

general |

|

Forging and rolling |

better |

general |

medium |

medium |

general |

low |

medium l quantities |

Ф100-200 |

higher |

general |

Process comparison

Productivity of various processes

The Productivity Of Forging Steel Ball Production Line

|

Projects |

50-70mm Forging ball |

50-90mm Forging ball |

70-110mm Forging Ball |

90-130mm Forging Ball |

110-150mm Forging Ball |

130-200mm Forging Ball

|

150-250mm Forging Ball |

||||||||||||||||||||||||||||

|

Steel Ball Diameter(mm) |

50 |

60 |

70 |

50 |

60 |

70 |

80 |

90 |

70 |

80 |

90 |

100 |

110 |

90 |

100 |

110 |

120 |

130 |

110 |

120 |

130 |

140 |

150 |

130 |

140 |

150 |

180 |

190 |

200 |

150 |

180 |

190 |

200 |

230 |

250 |

|

Productivity(n/min) |

8 |

7 |

6 |

10 |

8 |

7 |

5 |

4 |

8 |

6 |

5 |

4 |

3 |

6 |

5 |

4 |

3 |

2.4 |

5 |

4 |

3 |

2.5 |

2 |

4 |

3 |

3 |

2 |

1.5 |

1 |

4 |

3 |

2 |

1.5 |

1 |

1 |

|

Productivity per/h(Kg) |

246 |

373 |

507 |

308 |

426 |

592 |

631 |

719 |

676 |

757 |

898 |

986 |

984 |

1078 |

1232 |

1312 |

1278 |

1300 |

1640 |

1704 |

1625 |

1691 |

1664 |

2166 |

2029 |

2496 |

2875 |

2536 |

1972 |

3328 |

4313 |

3381 |

2958 |

2999 |

3851 |

The Productivity Of Rolling Steel Ball Production Line

|

Project |

ZQ30 |

ZQ40 |

ZQ50 |

ZQ60 |

ZQ80 |

ZQ120 |

|||||||||||||

|

Nominal diameter of blank (mm) |

20 |

25 |

30 |

25 |

30 |

40 |

30 |

40 |

50 |

40 |

50 |

60 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

|

productivity(n/min) |

110 |

110 |

110 |

110 |

110 |

85 |

110 |

85 |

75 |

85 |

75 |

72 |

70 |

65 |

60 |

50 |

45 |

40 |

40 |

|

Productivity per/h(Kg) |

244 |

477 |

824 |

477 |

824 |

1509 |

824 |

1509 |

2601 |

1509 |

2601 |

4314 |

4194 |

6185 |

8522 |

10112 |

12483 |

14769 |

19174 |

The Productivity of Forging and Rolling Steel Ball Production Line

|

project |

ZQ30 |

ZQ40 |

ZQ50 |

ZQ60 |

ZQ80 |

ZQ100 |

ZQ120 |

|||||||||||||||||

|

Nominal diameter of blank(mm) |

20 |

25 |

30 |

25 |

30 |

40 |

30 |

40 |

50 |

40 |

50 |

60 |

60 |

70 |

80 |

70 |

80 |

90 |

100 |

80 |

90 |

100 |

110 |

120 |

|

productivity(n/min) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

|

Productivity per/h(Kg) |

9 |

22 |

45 |

30 |

60 |

160 |

75 |

195 |

416 |

231 |

485 |

899 |

959 |

1618 |

2557 |

1808 |

2841 |

4247 |

6103 |

3267 |

4854 |

6935 |

9600 |

12943 |

Project case

Steel ball production line

Steel ball production line

Steel ball production line

Steel ball production line

Steel ball production line

Steel ball production line

Steel ball production line

Steel ball production line