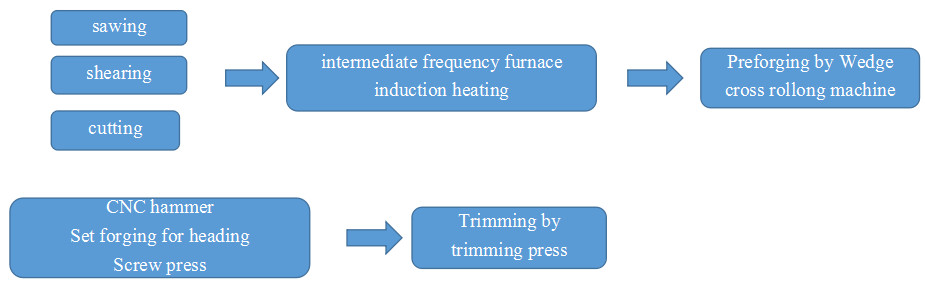

Big Head Shaft Technological Process

Sawing or cutting, medium frequency induction furnace heating, rolling by cross wedge rolling machine,upsetting by CNC forging hammer or screw press according to working piece,trimming

Big Head Shaft Process Flow Chart

Big Head Shaft Process Analysis

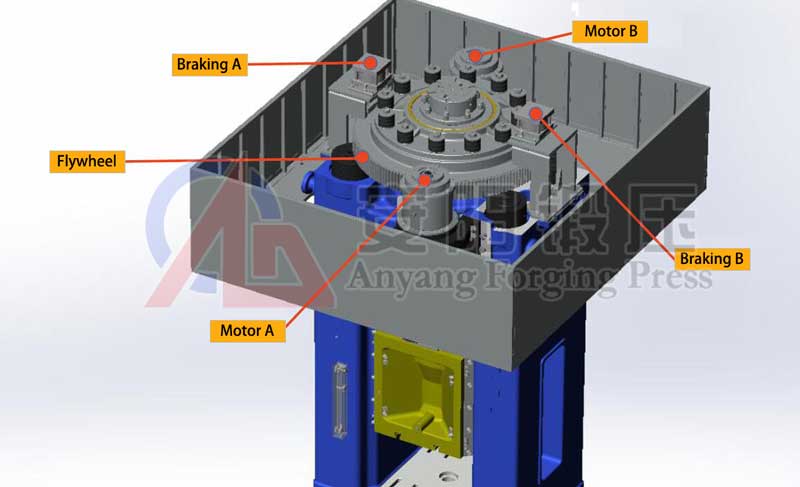

For big head shaft forgings,the key process is big end selection,preforging by cross wedge rolling machine. The percentage reduction of area should be less than 75%,Diameter variation less then 50%,Then the diameter of the forgings’ large end can be 5-6 times larger than the small end. When the larger end upsetting,the height-diameter ratio not more than 2.5.Electric screw press and CNC forging hammer has longer stroke,it is better for longer forgings putting in and taken out.Hot die forging press has short stroke and lower die assembly height,not better for long rod forgings.The lower die filling performance on hammer is bad,the long rod forging s has more steps and has large variation of diameter,the screw press is better for this kind of forgings.

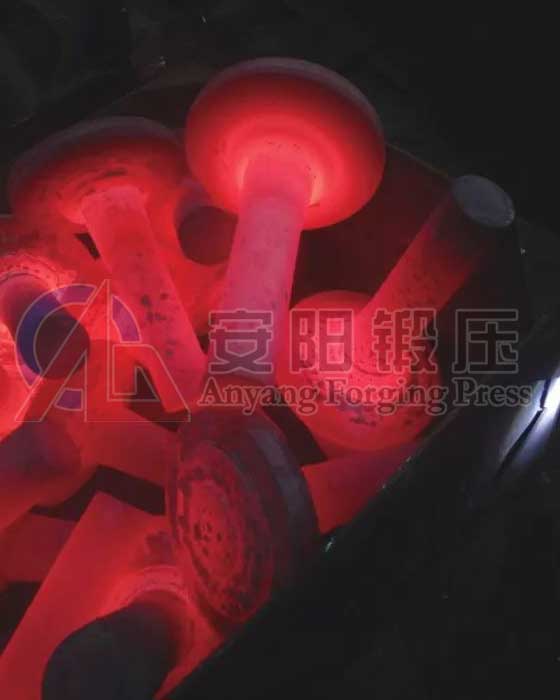

Project Case OF Big Head Shaft

Big head shaft production line

Major device links