Blank Forging Process - How to Choose Forging Machine and Process?

2019-11-21 17:32:10What is forging?

Forging is a processing method that uses hammers, anvils, punches or dies of forging machines to exert pressure on the blank to produce plastic deformation, so as to obtain the required shape and size of the workpiece. In the forging process of forging blank, the whole blank has obvious plastic deformation and a lot of plastic flow. In stamping, the blank is mainly formed by changing the spatial position of the area of each part, and there is no large distance plastic flow in the blank. Forging is mainly used to process metal parts, but also can be used to process some non-metals, such as engineering plastics, rubber, ceramics, brick and composite materials. Forging of forging blank and rolling and drawing in metallurgical industry belong to plastic processing, or pressure processing. However, forging is mainly used to produce metal parts, while rolling and drawing are mainly used to produce general metal materials such as plates, strips, pipes, profiles and wires.

History of forging machine

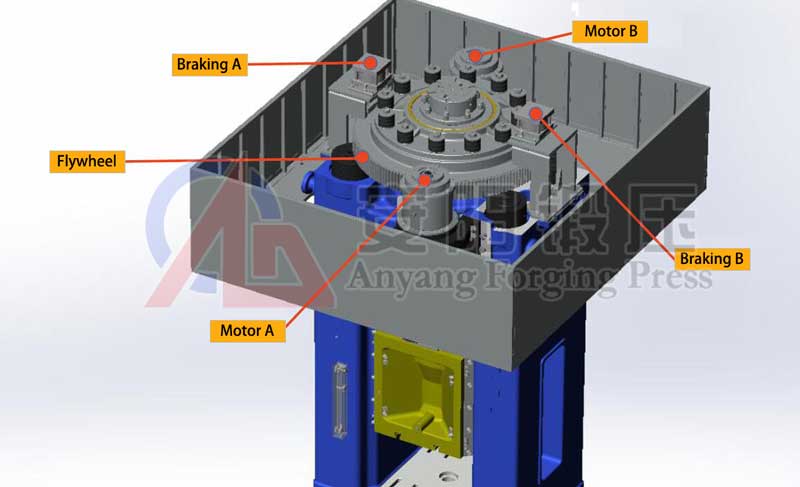

At first, people used to forge with a whirl hammer. Later, the method of lifting the heavy hammer by pulling the rope and pulley and then dropping it freely appeared. After the 14th century, animal power and hydraulic drop forging hammer appeared. In the early 20th century, with the mass production of automobile, hot forging developed rapidly and became the main forging technology. In the middle of the 20th century, the hot die forging press, flat forging machine and anvil less forging hammer gradually replaced the common forging hammer, which increased productivity and reduced vibration and noise. With the development of new forging processes, such as less and no oxidation heating technology, high precision and high life mold, hot extrusion, forming and rolling, as well as forging operators, manipulators and automatic forging production lines, the efficiency and economic effect of forging production continue to improve.

Selection conditions of forging blank

The materials of structural parts must have good malleability

Good malleability is the basic condition for the production of blank by forging. For example, cast iron, cast aluminum alloy, sliding bearing alloy and other metal materials with poor malleability can only be used to produce blanks by casting. All kinds of metal materials, such as structural steel, deformed aluminum alloy and pressure processing copper alloy, can be used to produce blank by forging. It can be seen that there is a direct relationship between the production method and material selection.

The shape of forging blank should not be too complex, especially the inner cavity structure.

For the parts with simple shape and single production property, the free forging method can be used to produce the rough parts. For the parts with complex shape and large batch production, we can choose the method of die forging or die forging to make the parts blank. In addition, the shape and structure of forgings shall be taken into account in accordance with the requirements of Section IV of this chapter for the structural processability of forgings.

Forging blanks of structural parts must be pre heat treated

In the forging process, because of the difference of the final forging temperature, deformation degree and cooling speed of each part of the forging, the defects such as uneven structure, residual internal stress and cold deformation strengthening will appear inside the forging. This will not only reduce the quality of forgings, but also bring difficulties to machining and final heat treatment. For this reason, forgings usually need proper heat treatment. Through the heat treatment after forging, the structure can be uniform, the grains can be refined, and the residual internal stress can be eliminated. So as to prepare for the final heat treatment (such as quenching). At the same time, due to the adjustment of forging hardness, the cutting performance can also be improved.

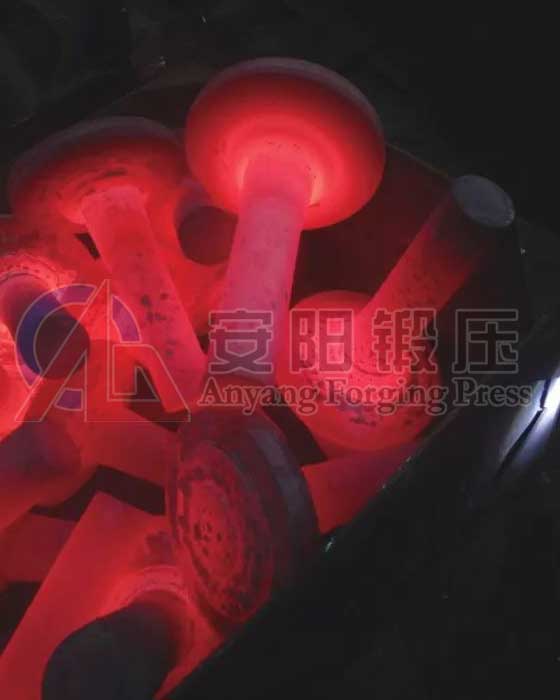

Roll forging machine for small blank forging

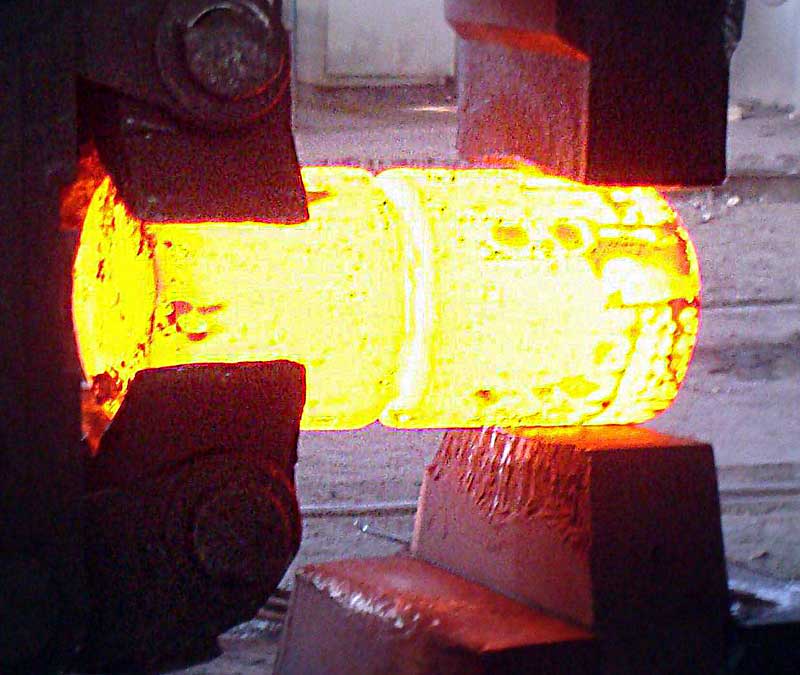

hydraulic press for large blank forging