Automatic Hot Forging Hammer & Production Line - Efficiency, Energy Saving, Safety

2019-08-10 14:57:48What Is automatic hot forging hammer?

Automatic full hydraulic die forging hammer is a high-tech product with independent intellectual property rights, which digests and absorbs the advanced technology of forging hammer at home and abroad. It is a new type of automatic forging machine to meet the requirements of high efficiency, energy saving and environmental protection in the forging industry.

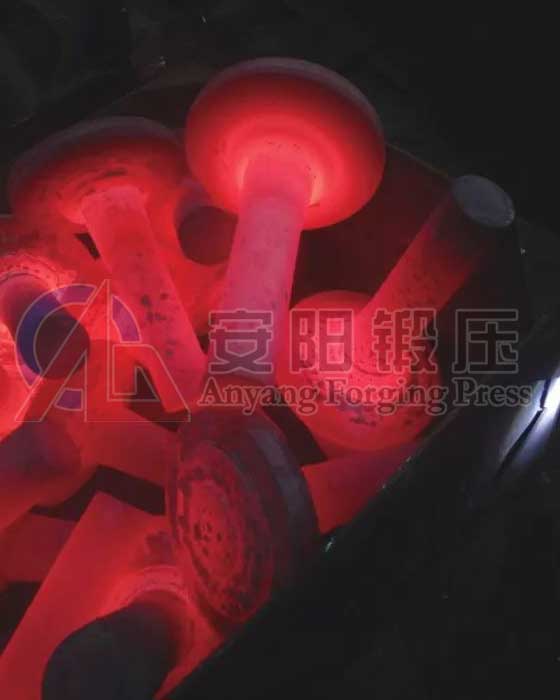

Application of automatic hot forging machine

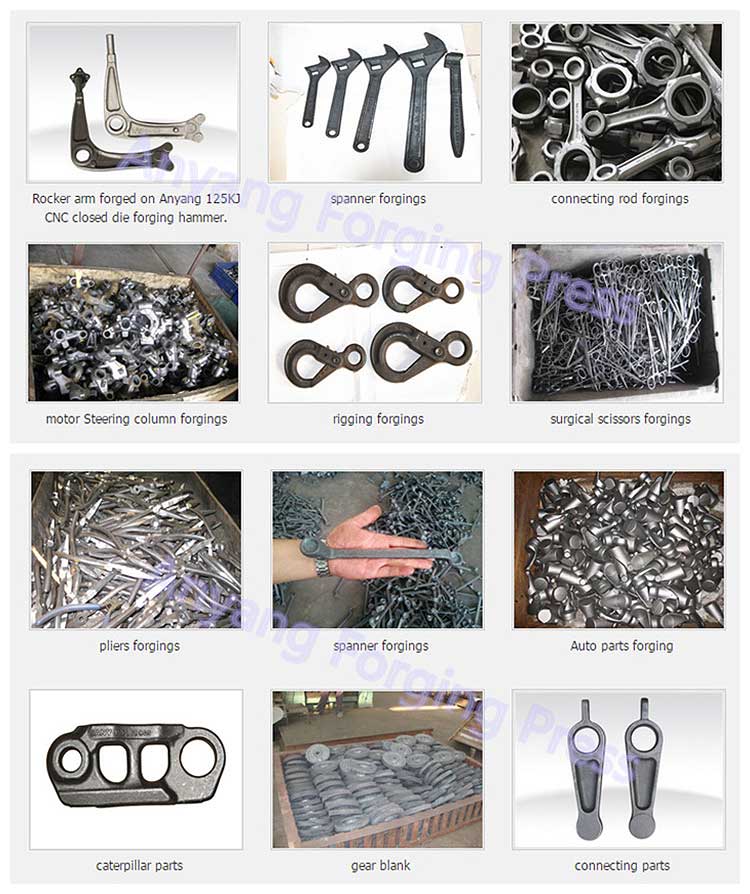

Anyang automatic hot forging hammers are widely used in various and mass production machine, hydraulic fittings, instrument hardware, construction hardware, daily use hardware, surgical instruments, kitchen hardware, famous tools, knives and other metal precision die forging industry. In addition to a wide range of high-density shaped parts applied in the aerospace industry, which is the core of automated precision forging production line equipment.

Best Automatic Forging Hammer Supplier from China

Anyang forging press is the top one manufacturer of hot forging machine. We exclusively drafted the national standard of full hydraulic automatic hot forging hammer in China. After more than 60 years of experience in forging equipment production and continuous technological upgrading and innovation,Anyang automatic forging hammer has reached the world's leading level of automatic hot forging hammer. We provide turn-key project service including design, manufacturing, installation, training, after-sale service and spare parts replacement.

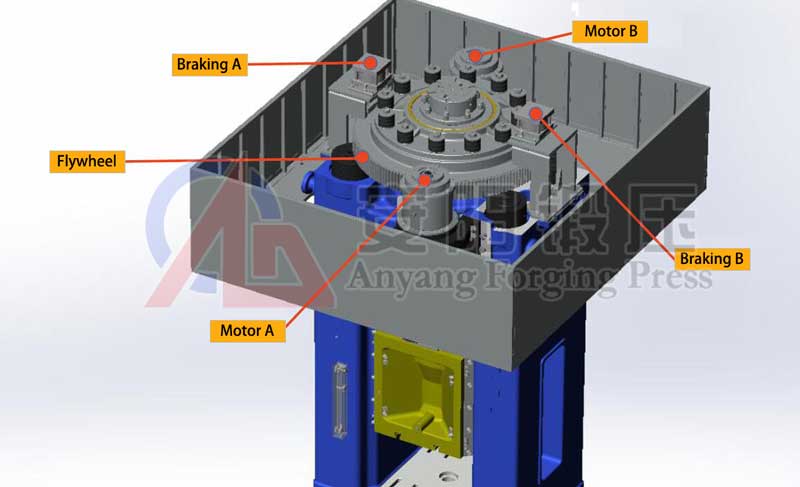

Unique Advantages of Anyang Automatic Forging Hammer

- High forging accuracy, 0.2 mm forging size error, 0.3% forging weight error, high surface finish.

- The strike energy can be superimposed. In the forging process, if the workpiece can not be hit at one time, it can be hit several times more, and the small forging hammer can make the large workpiece.

- It has a wide range of applications. Automatic full hydraulic die forging hammer can forge thin-walled forgings, special-shaped parts that are not easy to fill die cavity, thin rib forgings and forgings with strict tolerance requirements.

- The die of automatic hot forging hammer has a long service life.

- Automatic forging hammer has fast strike frequency and high production efficiency.

- The fuselage has good rigidity, strong anti-eccentric load ability and is suitable for multi-die cavity forging.

- The hammer rod is a flexible slender hammer rod structure without over-positioning and die stuffing.

- It can be forged at low temperature with high surface finish and stable chemical properties.

- The hitting energy can be controlled accurately and programmatically, the repetitive forging precision is good, and the quality of forgings is stable.

- The striking step and the energy per step can be controlled programmatically.

- The material utilization rate of die forgings is high.

- It reduces the requirement of forging hammer on the operation level of equipment for operators.

- The automatic production line can be formed by the integration of automatic full hydraulic forging hammer (programmable forging hammer) and forging robot.

Innovation of Anyang Automatic Hot Forging Hammer

- The design of special hitting valve system ensures the high precision of hitting energy of automatic forging hammer.

- The hitting control system adopts precise control system, which makes the hitting energy control precision extremely high. The hitting valve control system is separated from the main system. The unique control system makes the hitting energy more precise.

- The control valve adopts standardized design, while lowering the control link of the strike valve to the minimum.

- Hammer head buffer adopts outgoing structure, which overcomes the problem of unreliable inlaid welded structure.

- Buffer of hammer ram adopts outgoing structure, which overcomes the problem of unreliable inlaid welded structure.

- The accumulator is installed in a low position, which avoids the problem that the height of the accumulator increases sharply due to the super-high accumulator.

- The special bolt anti-loosening device makes the system more aseismic and safer.

- The energy can be automatically adjusted after replacing the die.

- The unique vibration function can effectively improve the clamping efficiency of the die.

Four New Breakthroughs in Automatic Forging Hammer Technology

In the forging machine, the die forging hammer is a widely used equipment. Its main features are fast forming speed, good metal fluidity and high forging quality, especially for the forging of thin-walled parts, which is irreplaceable by other equipment. However, the impact energy of ordinary die forging hammer cannot be precisely controlled. The forging hammer operator controls the striking energy by controlling the height of the ram. The technical requirements of the operator are relatively high, and the error is large, the production efficiency is low, and the automatic production line cannot be realized.

In particular, it should be pointed out that the forging environment is a very bad working condition, not only high temperature, but also vibration, noise, dust are very large, and has a certain risk. How to improve the technical level of forging equipment and realize forging automation and intelligence is particularly urgent and important. In the recent years, Anyang Forging Press has achieved four new breakthroughs in the aspects of high efficiency, energy saving and safety performance of automatic hot forging hammers, and has successfully developed the first automatic and intelligent forging production line of automatic hammers in China.

- Remote monitoring and fault diagnosis system for automatic forging hammer. Based on the Internet, two or more virtual local area networks (VLAN) are built through industrial remote communication module and security protocol, and industrial data security transmission and video surveillance are realized. The system can detect the operation of the equipment at any time, quickly judge the fault, shorten the downtime, maximize the utilization rate of the equipment, save the cost and reduce the loss for users.

- Short stroke control function of automatic forging hammer. Used for drawing and rolling extrusion in forging process.At present, the automatic forging hammer at home and abroad does not have this function, which limits the use of the automatic hot forging hammer. For forgings requiring elongation and rolling extrusion, additional blank-making equipment is needed. Successful development of this function enables the automatic forging hammer to complete blank-making, pre-forging, final forging and other processes, and expands the scope of application. It can not only control energy accurately, but also use it flexibly like a vacuum hammer.

- Automatic forging hammer strike energy detection system. It is mainly used to measure strike energy accurately in high vibration environment, instead of the original method that energy is measured by copper pillar, which not only saves copper pillar, but also greatly improves measurement accuracy. This method can also detect the repetitive accuracy of forging hammer strike energy, i.e. given the same strike energy, repeated operation for many times to see whether the actual impact energy fluctuation of hammer is within the standard range.

- Automatic hot forging hammer safety module function. It can reduce the accidents caused by misoperation in the process of NC hammer forging, thus avoiding the occurrence of safety accidents.

Parameters of Anyang Automatic Hot Forging Hammer

| CNC Hammer Model | C92K-12.5 | C92K-16 | C92K-20 | C92K-25 | C92K-31.5 | C92K-40 | C92K-50 | C92K-63 |

| Hit energy(KJ) | 12.5 | 16 | 20 | 25 | 31.5 | 40 | 50 | 63 |

| Weight of falling parts(kg) | 860 | 1080 | 1350 | 1700 | 2150 | 2700 | 3400 | 4300 |

| Max hit number(min-1) | 129 | 122 | 123 | 113 | 100 | 98 | 98 | 98 |

| Hit stroke(mm) | 420-620 | 435-635 | 455-665 | 470-685 | 490-755 | 510-790 | 530-775 | 550-805 |

| Working oil pressure(Mpa) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Main motor power(KW) | 37 | 37 | 55 | 55 | 55 | 75 | 2*55 | 2*55 |

| Machine weight(kg) | 19000 | 27000 | 30000 | 39300 | 48000 | 63000 | 78500 | 95000 |

| | ||||||||

| CNC Hammer Model | C92K-80 | C92K-100 | C92K-125 | C92K-160 | C92K-200 | C92K-250 | C92K-320 | C92K-400 |

| Hit energy(KJ) | 80 | 100 | 125 | 160 | 200 | 250 | 320 | 400 |

| Weight of falling parts(kg) | 5400 | 6800 | 8500 | 10800 | 13700 | 17100 | 21000 | 27000 |

| Max hit number(min-1) | 92 | 81 | 70 | 70 | 60 | 50 | 45 | 40 |

| Hit stroke(mm) | 570-835 | 595-885 | 615-920 | 640-960 | 740-1060 | 770-1100 | 740-1150 | 860-1200 |

| Working oil pressure(Mpa) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Main motor power(KW) | 2*90 | 2*90 | 2*132 | 3*90 | 4*90 | 4*90 | 4*110 | 6*110 |

| Machine weight(kg) | 120000 | 148000 | 195000 | 235000 | 275000 | 330000 | 410000 | 465000 |

Automatic Hot Forging Hammer Intelligent Production Line

The above four new technologies and measures of hydraulic automatic forging hammer have been applied in user equipment, which have been well reflected and affirmed by users. Based on these new technologies, after two years of research and development and debugging, An Forging Company has designed and produced the first automatic forging production line of CNC hammer operated by robots in China. This production line can complete precision forging of die forgings, realize unmanned and automatic forging operation, improve efficiency, improve working environment and conform to forging. In line with the development trend of forging market, the market has broad prospects.

Now, more and more customer choose Anyang Forging Press to built their automatic forging hammer production line. We provide automatic forging production line for steel ball making, connecting rod, gears, flange, etc. Whatever you want to make on automatic forging hammer production line, contact us, we will try our best to help you!

Automatic Forging Hammer Production Line is Making Knives

Automatic Forging Hammer Production Line Collection