How to make flange use ring rolling forging or forging hammer machine

2017-11-13 11:27:05

How to make flange use ring rolling forging or forging hammer machine

Anyang Forging Press Machinery Industry Co., Ltd produce ring rolling machine and cnc hydraulic die forging hammer machine , as forging hammer manufactures , we have many customer that use our ring rolling forging or forging hammer for sale to product flange .

When producing flange , how to select forging machine ? how to select size ?

(1 ) Forging hammer machine is suit for you , if you produce small size flange .

Small flange technological process

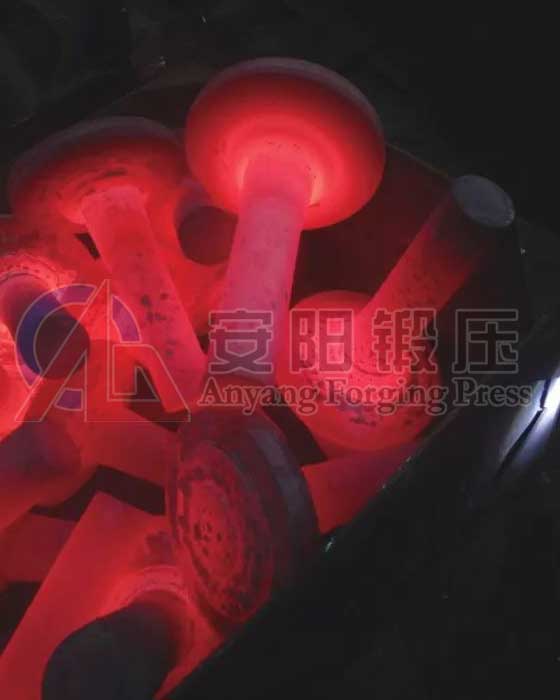

Small flange, can be formed directely by the forging die with high production efficiency. It can use the open or close die forging. When forge a small flange,we can use intermediate frequency furnace induction heating, But the stainless steel flange can use otherhesting for the intermediate frequency furnace is inefficiency. There are 2 steps, preforging and final forging, Can be finished in one hammer or screw press, also can be preforged in one equipment,and otherone final forging, triming and fiercing.

(2) Forging hammer machine or ring rolling machine is suit for you , if you produce Midium flange

Midium flange technological process

Midium flange, can be formed directely by the forging die,or formed by ring rolling after forging. According to the material and weight, chose the propriate furnace. When directely forging,there’s preforging and final forging can be finished indifferent equipment. The preforging can use open or close forging, the final fofrging always usehammer or screw press. The rolling forming flange, can be preforging by swadge forging,big hammer or screw press,the rolling to the final shape.

(3) ring rolling machine is suit for you , if you produce large flange

large flange technological process

large flangelineis made up by special hydraulic press, CNC ring rolling machineand charger. It is always heating by Chamber forging furnace or forging-type forging furnace,then the charger put the material to the special press for upsetting, piercing then formed by CNC ring rolling press machine.

Ring rolling mill are divided into the radial rolling and radial-axial rolling(D53K series,CNC controlled). The radial rolling are divided into vertical type (D51 series) . ring roller can produce Dimension of Ring OD 45MM-5000MM , Dimension of Ring Height 35mm-750mm .

Our ring roller for sale have exported to USA, Canada, Mexico, Brazil, Chile, UK, Germany, France, Italy, Norway, Romania, Russia, Slovenia, Burma, India, Pakistan, Egypt, South Africa etc., totally more than 74 countries and regions. And forging hammer have obtained CE Certificate.

We also can apply forging machines as below:

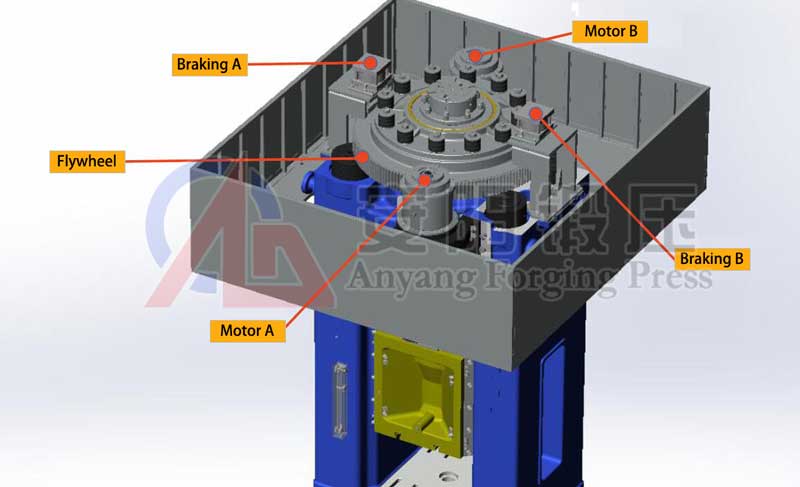

1.J58K series CNC electric mechanical precision screw press

2. C92K CNC fully hydraulic die forging hammer

3. C86 hydraulic close die forging hammer

4. C66 hydraulic open die forging hammer

5. Y13 hydraulic open die forging press

6. C41 pneumatic forging power hammer

7. T31 forging manipulator

8. ZQ steel ball skew rolling machine

9. D51 and D53 ring rolling machine

10. ZGD automatic roll forging machine

11. D46 cross wedge rolling machine

12. T92Y high speed hydraulic riveting machine

13. Y81 and Y83 series metal recycling press machine

14. Q42 series billet cold shearing line

15. JH21 series open type high performance press with fixed bed

16. JC31 series closed type trimming press

2. C92K CNC fully hydraulic die forging hammer

3. C86 hydraulic close die forging hammer

4. C66 hydraulic open die forging hammer

5. Y13 hydraulic open die forging press

6. C41 pneumatic forging power hammer

7. T31 forging manipulator

8. ZQ steel ball skew rolling machine

9. D51 and D53 ring rolling machine

10. ZGD automatic roll forging machine

11. D46 cross wedge rolling machine

12. T92Y high speed hydraulic riveting machine

13. Y81 and Y83 series metal recycling press machine

14. Q42 series billet cold shearing line

15. JH21 series open type high performance press with fixed bed

16. JC31 series closed type trimming press

We also can supply skew rolling production line for grinding balls, automatic forging line for gears, bearing rings etc closed die forgings.

if you want to learn more ,,please contact 0086-372-3389658

whatsapp : +8618317777443

wechat:+8618317777443

email : sophia@anyanghammer.com

website : www.chinesehammers .com